Superior Manufacturing

Superior European-class Cars. Building the

Chinese People’s Preferred Vehicle.

Beginning with

a high baseline, as well as compliance

with the highest international

quality standards and an aim to implement informationized Industry

4.0 management, Hanteng Autos has,

through international sourcing of parts and consolidation of the production

process,developed a vehicle production line

compliant with European quality standards. Hanteng Autos currently runs four

state-of-the-art workshops, and possesses the capacity to

manufacture small-displacement,

high-performance engines.

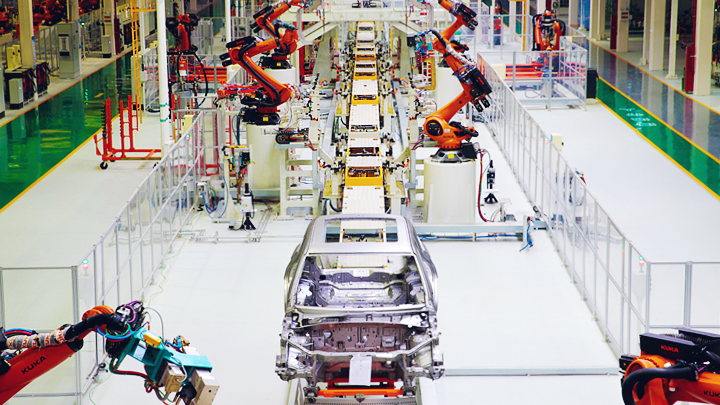

Superior products have a solid foundation. Thus far, the first phase of the Hanteng Automobile Industry Park has been completed, which houses four state-of-the-art workshops in terms of completeness, efficiency, environmental friendliness and automation, reaching the mainstream domestic standardin both equipment and quality assurance, with an estimated annual production capacity of 150,000 units. The second phase, set to break ground in 2017, has a planned capacity of 300,000 units per annum. Following the completion of the second phase, Hanteng Autos will be comprised of four core business divisions,including traditional fuel cars, NEVs, engines and automotive parts, with a total annual production capacity of 450,000 units.

A Rising Star, Not Like the

Others. Based

on the

foundation of

traditional automobile production management, Hanteng Autos leverages

second-mover advantages and

has undertaken a comprehensive implementation of of

the Industry 4.0 informatization management principles, designing a

production line equipped to

fully benefit from the latest information technologies and solutions including ERP,

PRM, DMS and MES, in order to realise

an organic management ecosystem in

terms of industry, production and operation.

-

Stamping Shop

Hanteng Autos’ stamping workshop is equipped with the leading robotic assembly line nationwide, with an automation rate close to 100%. -

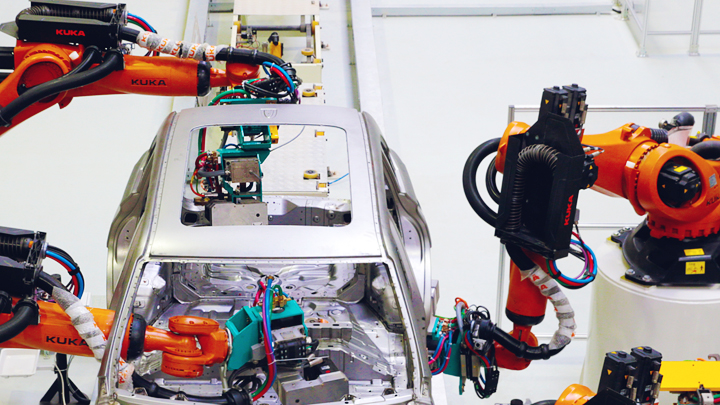

Welding Shop

The welding shop adopts the Open-Gate technology from Comau, using a flexible manufacturing system to deliver simultaneous production across three manufacturing platforms, with automation rate exceeding 90%.

-

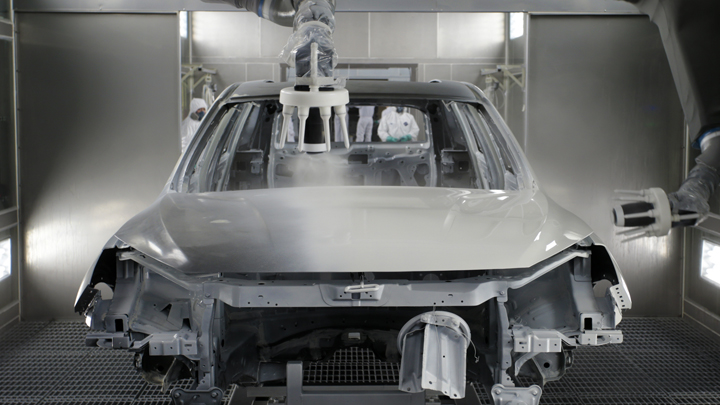

Coating Shop

The coating shop, which covers key processes such as varnish, floating coat, finishing coat, and door and closure coat, is 100% automated and reaches an internationally advanced level.

-

Assembly Shop

The assembly shop, equipped with a fiber-optic communication based control system, is capable of automatic assembly of cars according to production instructions and real-time monitoring, thus assuring production quality.

Stringent Measures. Superior Quality.

In compliance with the general principle of “foremost prevention and continuous improvement”, Hanteng Autos has a rigorous and comprehensive quality assurance system covering every step from R&D to supplier selection and manufacturing, to ex-factory inspection, with quality control that surpasses the national standard.

Hanteng Autos has

implemented four management requirements,

including the ISO 9000-2008

quality management system, the ISO

14000-2004 environmental management system, the ISO 18000-2011 Occupation

Health Safety Management System and the GB/T23331-2012

energy management system.

Hanteng Autos develops new products by means of a systematic, well-informed and forward-looking approach, by solving problems faced by competitors, implementing class-leading quality standards and building eight innovative R&D nodes. As part of its quality assurance system, Hanteng Autos uses automotive parts from world-leading suppliers, organising supplier training sessions and signing quality agreements with partners. During the manufacturing process, Hanteng Autos ensures 100% vehicle inspection according to its higher-than-national quality standards, which are comprised of a series of industry-first “four extreme” tests, including extreme low and high temperatures heat, high altitude and intense salt spray testing.